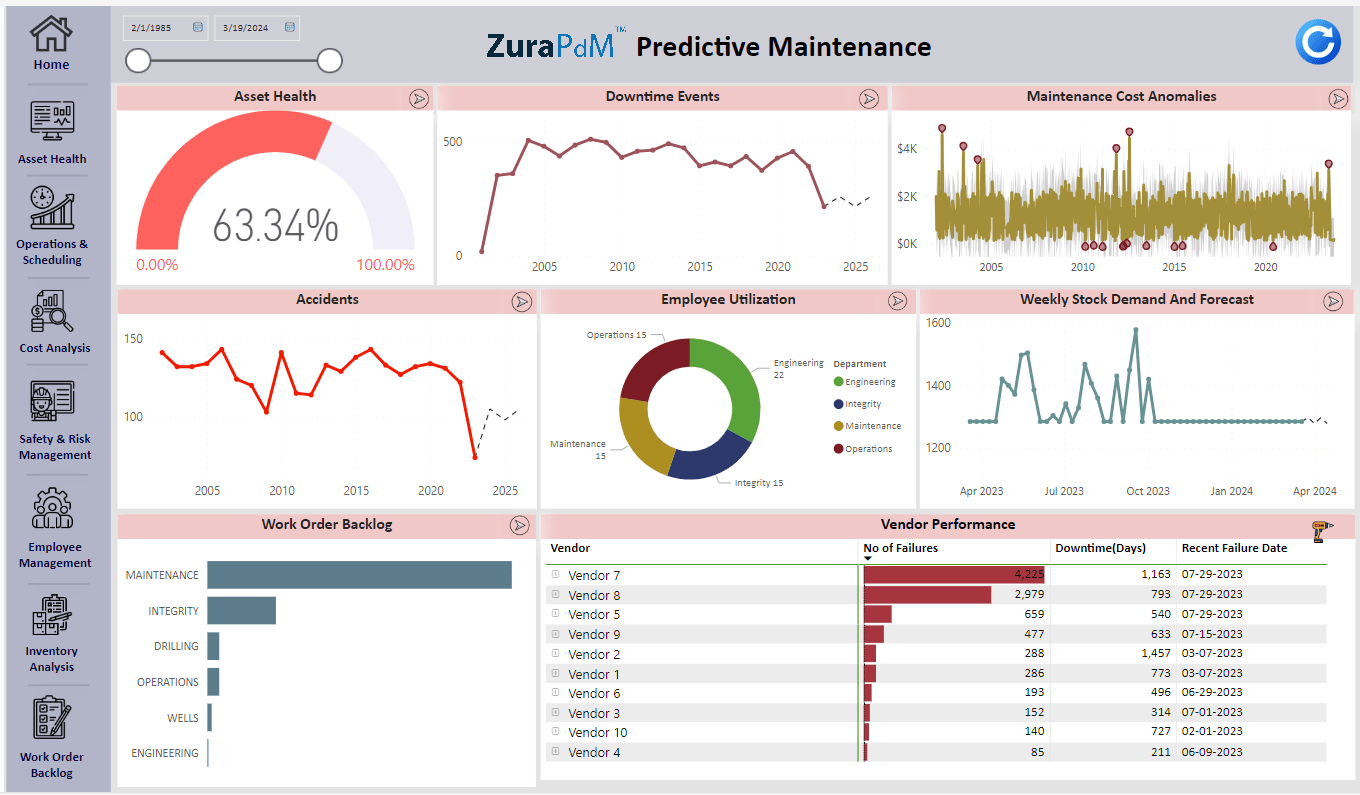

Maintenance professionals need the ability to identify potential equipment failures. They need to understand the evolving patterns of equipment failure and thereby prioritize maintenance tasks.

Zura has mastered leveraging the key data points – lifetime data, run-to-failure data, threshold data required for RUL prediction. We use the proportional hazard models and probability distributions of component failure times to estimate RUL from lifetime data. Using a database of run-to-failure data from similar components or different components showing similar behavior, we estimate RUL using similarity methods. In absence of run-to-failure data or lifetime data, the information on prescribed threshold values is monitored continuously to predict potential failures and estimate RUL. Our expertise in working with Machine learning (ML) solutions enables real-time monitoring and proactive decision-making. Our solutions are trained to learn relationships between variables and failure events, accurately forecasting equipment failure likelihood or RUL.