MRO thrives on Strong Data Foundation

Organizations are increasingly adopting digital transformation in MRO (Maintenance, Repair and Operations) for enhanced flexibility and resilience. Be it cloud based, remote monitoring, virtual inspections, augmented reality – MRO teams are increasingly embracing these new age technologies for troubleshooting, training, and remote assistance in maintenance tasks. Predictive maintenance continues to evolve with advancements in artificial intelligence (AI) and machine learning (ML) and organizations utilize more sophisticated algorithms to predict equipment failures, optimize maintenance schedules, and reduce downtime.

MRO thrives on Strong Data Foundation

Organizations are increasingly adopting digital transformation in MRO (Maintenance, Repair and Operations) for enhanced flexibility and resilience. Be it cloud based, remote monitoring, virtual inspections, augmented reality – MRO teams are increasingly embracing these new age technologies for troubleshooting, training, and remote assistance in maintenance tasks. Predictive maintenance continues to evolve with advancements in artificial intelligence (AI) and machine learning (ML) and organizations utilize more sophisticated algorithms to predict equipment failures, optimize maintenance schedules, and reduce downtime.

MRO Solutions by Role

Data analytics and artificial intelligence play a crucial role in optimizing MRO processes. Organizations are effectively leveraging these technologies for predictive maintenance, trend analysis, and continuous improvement in maintenance strategies. Zura Labs understands this, and we have built solutions that can metamorphize MRO at multiple levels.

Data analytics and artificial intelligence play a crucial role in optimizing MRO processes. Organizations are effectively leveraging these technologies for predictive maintenance, trend analysis, and continuous improvement in maintenance strategies. Zura Labs understands this, and we have built solutions that can metamorphize MRO at multiple levels.

Middle Managers

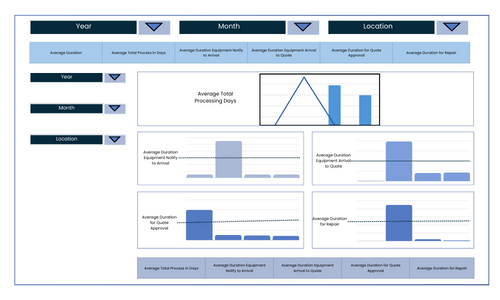

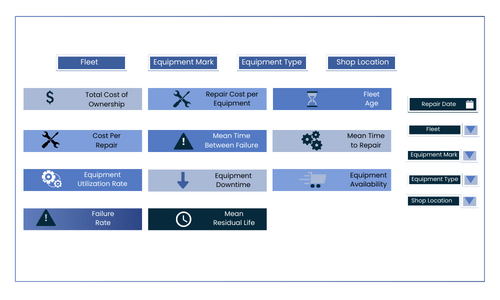

Middle managers can gain a clear view of their specific MRO areas with the help of our tools. You can analyze the data specific to your department and grasp the overall performance with high-level summaries. Our solutions also provide you with the ability to perform a drill-down analysis and monitor to identify potential issues proactively.

Analysts

We have solutions that can store mountains of data collected by inspectors, technicians, and analysts. Analyst teams can delve into this data to uncover hidden patterns and trends. MRO experts can filter and explore the data from every single angle using multiple slicers and parameters to get a microscopic view of the data. Your equipment’s health can be determined by identifying crucial patterns via time-series charts and heatmaps.

Executives

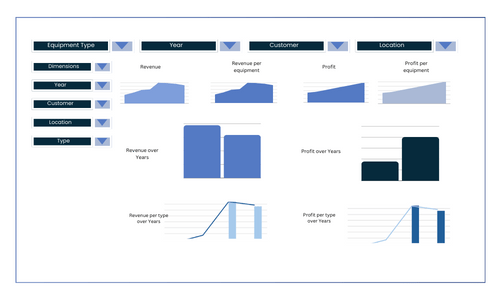

Our strategic MRO solutions help leadership teams gain a comprehensive view of the entire MRO operation. You will be able to see the holistic performance of MRO across all the departments and business units and monitor KPIs to ensure your organization is on track with its long-term goals. Our solutions help you track trends and analyze period-over-period changes to identify the areas of improvement and benchmark performance against established goals.

Middle Managers

Middle managers can gain a clear view of their specific MRO areas with the help of our tools. You can analyze the data specific to your department and grasp the overall performance with high-level summaries. Our solutions also provide you with the ability to perform a drill-down analysis and monitor to identify potential issues proactively.

Analysts

We have solutions that can store mountains of data collected by inspectors, technicians, and analysts. Analyst teams can delve into this data to uncover hidden patterns and trends. MRO experts can filter and explore the data from every single angle using multiple slicers and parameters to get a microscopic view of the data. Your equipment’s health can be determined by identifying crucial patterns via time-series charts and heatmaps.

Executives

Our strategic MRO solutions help leadership teams gain a comprehensive view of the entire MRO operation. You will be able to see the holistic performance of MRO across all the departments and business units and monitor KPIs to ensure your organization is on track with its long-term goals. Our solutions help you track trends and analyze period-over-period changes to identify the areas of improvement and benchmark performance against established goals.

Learn about how Maintenance, Repair and Operations (MRO) underwent a transformation over the last three decades. Have you joined the band wagon yet?

Learn about how Maintenance, Repair and Operations (MRO) underwent a transformation over the last three decades. Have you joined the band wagon yet?

MRO – Key Focus Areas

- Equipment Failure

- Downtime

- Operational Costs

- Skilled Personnel

- Maintenance Tasks

- Inventory

- Technology

- Insights

The MRO space witnessed a transformation in terms of predicting equipment failure. During the early days, maintenance crew sprang into action only after the equipment failed. With the advent of new predictive maintenance techniques, MRO professionals can now identify the likelihood of equipment failure resulting in reliability-centric maintenance. Zura’s suite of solutions encompasses several predictive techniques such as Survival Analysis, Remaining Useful Life, Root Cause Analysis delivering a host of benefits to MRO professionals.

Rudimentary maintenance approaches led to high incidents of downtime. The equipment is continually monitored, with complex algorithms accurately predicting maintenance needs, helping achieve minimum downtime. Our Downtime Events and Forecast lets MRO professionals get real-time insights of downtime events allowing them to achieve minimum downtime.

Routine maintenance activities were reactive in nature leading to spike in operational costs. Condition- based maintenance where MRO professionals relied on real-time data helped drastically reduce operational costs. Zura’s solution suite encompasses a wide variety of financial insights such as Budget Vs Expenses, Maintenance Cost Anomalies , Expense Forecast for MRO teams to make informed decisions.

Reactive maintenance strategies saw a growing strife in finding skilled personnel and utilizing them effectively. With the advent of some new age technologies such as IoT sensors and AI, MRO teams were able to perform better. Zura’s comprehensive insights into Employee Utilization and Employee Management gave leaders a deep dive idea into how the teams were performing and their productivity.

The availability of high-quality data coupled increased use of artificial intelligence helped improve MRO strategies. MRO teams are increasingly adopting data-driven maintenance management solutions to have tangible results directly impacting their bottom lines. Our insights specific to Asset Health, Maintenance Scheduling ensure there are enough resources and space to perform maintenance tasks efficiently.

MRO inventory thrives on knowing your most used parts, stock status, and part movement. Analyzing usage data helps prioritize stocking high-demand parts, while real-time stock control ensures no run out. Tracking parts movement, from usage to returns, empowers identifying inefficiencies and optimize inventory levels. This translates to less downtime, lower costs, and a smoother-running MRO operation.

MRO teams deploy advanced maintenance strategies that use data analytics to identify potential problems before they occur. This proactive approach allows for faster response times, better asset performance and lower overall costs associated with unexpected downtime or equipment failure. Zura leverages the combination of artificial intelligence, machine learning and advanced analytics to transform traditional maintenance approaches to a proactive and predictive process.

Smart Narratives unlock valuable MRO insights by automatically summarizing data and highlighting key trends. This saves time analyzing MRO details and enables focus on strategic decisions. From cost-saving strategies to equipment maintenance, Smart Narratives tailor insights for specific needs, keeping facilities and equipment running smoothly.

- Equipment Failure

- Downtime

- Operational Costs

- Skilled Personnel

- Maintenance Tasks

- Inventory

- Technology

- Insights

The MRO space witnessed a transformation in terms of predicting equipment failure. During the early days, maintenance crew sprang into action only after the equipment failed. With the advent of new predictive maintenance techniques, MRO professionals can now identify the likelihood of equipment failure resulting in reliability-centric maintenance. Zura’s suite of solutions encompasses several predictive techniques such as Survival Analysis, Remaining Useful Life, Root Cause Analysis delivering a host of benefits to MRO professionals.

Rudimentary maintenance approaches led to high incidents of downtime. The equipment is continually monitored, with complex algorithms accurately predicting maintenance needs, helping achieve minimum downtime. Our Downtime Events and Forecast lets MRO professionals get real-time insights of downtime events allowing them to achieve minimum downtime.

Routine maintenance activities were reactive in nature leading to spike in operational costs. Condition- based maintenance where MRO professionals relied on real-time data helped drastically reduce operational costs. Zura’s solution suite encompasses a wide variety of financial insights such as Budget Vs Expenses, Maintenance Cost Anomalies , Expense Forecast for MRO teams to make informed decisions.

Reactive maintenance strategies saw a growing strife in finding skilled personnel and utilizing them effectively. With the advent of some new age technologies such as IoT sensors and AI, MRO teams were able to perform better. Zura’s comprehensive insights into Employee Utilization and Employee Management gave leaders a deep dive idea into how the teams were performing and their productivity.

The availability of high-quality data coupled increased use of artificial intelligence helped improve MRO strategies. MRO teams are increasingly adopting data-driven maintenance management solutions to have tangible results directly impacting their bottom lines. Our insights specific to Asset Health, Maintenance Scheduling ensure there are enough resources and space to perform maintenance tasks efficiently.

MRO inventory thrives on knowing your most used parts, stock status, and part movement. Analyzing usage data helps prioritize stocking high-demand parts, while real-time stock control ensures no run out. Tracking parts movement, from usage to returns, empowers identifying inefficiencies and optimize inventory levels. This translates to less downtime, lower costs, and a smoother-running MRO operation.

MRO teams deploy advanced maintenance strategies that use data analytics to identify potential problems before they occur. This proactive approach allows for faster response times, better asset performance and lower overall costs associated with unexpected downtime or equipment failure. Zura leverages the combination of artificial intelligence, machine learning and advanced analytics to transform traditional maintenance approaches to a proactive and predictive process.

Smart Narratives unlock valuable MRO insights by automatically summarizing data and highlighting key trends. This saves time analyzing MRO details and enables focus on strategic decisions. From cost-saving strategies to equipment maintenance, Smart Narratives tailor insights for specific needs, keeping facilities and equipment running smoothly.

Unlocking Operational Efficiency through Predictive Maintenance

Zura' Expertise

Maintenance KPIs – Measure the performance of your maintenance efforts.

Equipment Costing Trends and Analysis – Understand the cost of operating and maintaining the equipment over time .

Predictions of Remaining Useful Life – Estimate how long an equipment will last before there is a need to replace it.

Bad Actors and Anomalies Detection – Identify the equipment with abnormal behavior and potential of failure.

Forecasting – Predict future demand for maintenance services and resources.

Facility and Capacity Planning – Ensure there are enough resources and space to perform maintenance tasks efficiently.

Recommendations of Scrap Candidates – Identify equipment that is worn out or damaged and is worth repairing.

Geometry Tracking – Monitor the physical condition of the equipment to identify potential problems.

Automation of Maintenance Alerts – Automate the process of responding to maintenance alerts and scheduling maintenance tasks.

Zura' Expertise

Maintenance KPIs – Measure the performance of your maintenance efforts.

Equipment Costing Trends and Analysis – Understand the cost of operating and maintaining the equipment over time .

Predictions of Remaining Useful Life – Estimate how long an equipment will last before there is a need to replace it.

Bad Actors and Anomalies Detection – Identify the equipment with abnormal behavior and potential of failure.

Forecasting – Predict future demand for maintenance services and resources.

Facility and Capacity Planning – Ensure there are enough resources and space to perform maintenance tasks efficiently.

Recommendations of Scrap Candidates – Identify equipment that is worn out or damaged and is worth repairing.

Geometry Tracking – Monitor the physical condition of the equipment to identify potential problems.

Automation of Maintenance Alerts – Automate the process of responding to maintenance alerts and scheduling maintenance tasks.

Road to MRO Transformation

Why Zura?

Comprehensive Expertise – Data Engineering, Analytics and Automation solutions tailored for the maintenance, repairs, and operations (MRO) domain, ensuring your equipment and processes run smoothly and efficiently.

Preventive/Predictive Maintenance – Leverage advanced maintenance techniques to foresee potential equipment failures, reducing downtime, and extending the lifespan of your machinery.

Data-Driven Insights – Solutions to provide actionable insights by analyzing data from your operations, helping you make informed decisions and improve overall efficiency.

Proven Track Record – Strong history of successful projects in the MRO domain, where clients achieved significant improvements in productivity and cost savings.

Innovation and Agility – Our approach combines innovation with agility, allowing us to quickly adapt to new technologies, ensuring that your operations stay ahead of the competition.

Custom Solutions – We recognize that your manufacturing operation is your own and unique. Our team works closely with you to develop customized analytics solutions that address your specific challenges and objectives.

Take the first step towards improving your MRO!

Take the first step towards improving your MRO!

Talk to us!

Fill up this quick form and we will reach out to you!

MRO Solution Suite

Configurable Parameters, Dimensions, Measures, and Filters.

Template Driven Solution

Template Based Dashboard Authoring

Data Mart / Data Warehouse Compatibility