In asset-heavy industries, unexpected equipment failures, high repair costs, and maintenance delays are more than just operational headaches. They are risks to performance, safety, and profitability. As businesses grow more complex, the need for smarter, faster maintenance strategies becomes critical. That’s why many forward-looking organizations are now shifting from reactive fixes to AI and analytics driven predictive strategies that help them anticipate issues, optimize resources, and extend asset life.

Reliability and Maintenance professionals across industries, require detailed insights into some key aspects such asvasset health, asset downtime, maintenance anomalies, and employee adoption to avoid rude surprises that can turn into high operational risks. There is continuous exploration for methods to improve equipment reliability and reduce maintenance costs.

Several asset intensive industries like chemicals, mining, paper and pulp, power production, utilities, oil and gas, maintenance and repair shops, and manufacturing are engaging with expert technology and analytics providers to develop long-term strategies for their maintenance operations.

Some critical key focus areas shaping smarter maintenance decisions

Remaining Useful Life (RUL)

Maintenance professionals need the ability to identify potential equipment failures. They need to understand the evolving patterns of equipment failure and thereby prioritize maintenance tasks.

Key data points such as lifetime data, run-to-failure data, and threshold data are essential for accurate RUL (Remaining Useful Life) prediction. Proportional hazard models and probability distributions of component failure times are often used to estimate RUL from lifetime data. When a database of run-to-failure data is available, either from similar components or those showing similar behavior, similarity methods can be applied to estimate RUL. In the absence of such data, monitoring prescribed threshold values over time helps predict potential failures.

Machine learning (ML) solutions support this process by enabling real-time monitoring and proactive decision-making, learning the relationships between variables and failure events to improve RUL forecasting accuracy.

Bad Actors or Scrap Recommendations

Detecting equipment failures before they happen can be challenging when unexpected breakdowns occur, and this difficulty arises due to various factors. Lack of proactive maintenance measures and insights related to scrapable equipment and/or parts can result in equipment breakdowns.

Advanced monitoring and proactive maintenance techniques, combined with buffer time, can help predict and prevent equipment breakdowns. Analytics solutions that process historical transaction data and other relevant features are used to identify patterns associated with bad actor scenarios. Real-time monitoring powered by predictive models can help detect possible breakdowns early. By analyzing production data, sensor readings, and quality metrics, these models can identify patterns linked to defects or suboptimal performance. Predicting potential defects in advance enables maintenance teams to take corrective actions and reduce scrap.

Lifecycle Management

When does fixing equipment become a more cost-efficient decision compared to scrapping it? Furthermore, can we identify equipment with usable parts that can be repurposed to extend the lifespan of other equipment?

Advanced cost analysis algorithms can help inform such decisions by evaluating repair vs. replacement value in real time. Identifying reusable components not only helps extend machine longevity but also reduces waste and optimizes overall maintenance costs.

Scheduled Maintenance & Survival Analysis

A key priority for maintenance professionals is optimizing equipment reliability by continuously analyzing data and focusing on critical assets. Real-time health assessments help identify, detect, and address issues as they occur, minimizing disruption.

Accurately forecasting the future condition of equipment is essential to reducing operational risks, avoiding unplanned downtime, and controlling costs. AI-powered analytics & machine learning together can combine sensor data with operational data to predict equipment failures and refine maintenance schedules. Techniques such as survival analysis help estimate remaining useful life (RUL), while optimization models are used to align maintenance activities with production downtimes and resource availability.

Root Cause Analysis

Even with the most reliable assets, equipment failure is inevitable over time. Traditionally, maintenance professionals have relied on manual troubleshooting, by using issue trees, site visits, and trial-and-error methods to isolate problems.

Root cause analysis (RCA) provides a more systematic approach to prevent recurring malfunctions, especially those linked to abnormal usage patterns. It helps minimize costly downtime for critical systems and supports better budget control. By combining data-driven techniques, deep learning models, and domain expertise, RCA enhances predictive maintenance strategies. Machine learning algorithms and feature importance analysis can help pinpoint failure causes and highlight the key factors contributing to breakdowns, allowing teams to improve system reliability and reduce future risks.

Anomaly Detection

Predictive maintenance encompasses having warning systems in place for upcoming malfunctions and the ability to spot anomalies and uncommon trends in machine data. Maintenance professionals can now take proactive measures to prevent disruptions and optimize maintenance strategies.

![]()

Maintenance professionals should learn from historical data patterns and predict potential anomalies in real-time operations. You should leverage AI algorithms and data visualizations for identifying anomalies. The Power BI anomaly detection algorithm is based on the SR-CNN algorithm, which is rooted in computer vision and identifies the items that stand out. Maintenance departments can rely on unsupervised learning models for anomaly detection. These models predict unknown disruptive events based on normal functioning data, some of the popular ones being proximity-based, hybrid (statistical + proximity) and transformer methods. Exploratory Data Analysis (EDA) analyzes visual patterns of signals to detect anomalies and deviations. Improved connectivity, cloud computing and data analytics have fueled anomaly detection, and a combination of AI models, unsupervised learning, EDA, and collaboration can help organizations detect anomalies early and prevent equipment failures.

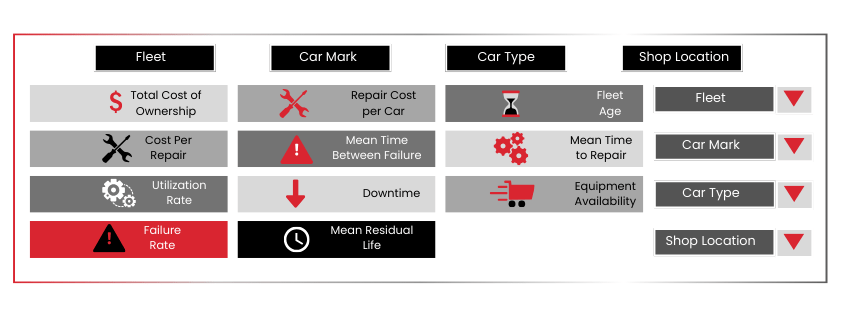

Key Performance Indicators

One of the most common mistakes maintenance teams make is to focus on a single KPI without considering the bigger picture.

More often than not there is lot of focus on increasing meantime between failures (MTBF) which in most cases leads to postponing preventive maintenance tasks and potentially resulting in larger breakdowns. What should be done instead is to employ a balanced scorecard method with KPIs for equipment health, maintenance effectiveness, and cost reduction. Regular benchmarking ensures alignment with long-term predictive maintenance goals, maintaining focus on the big picture.

Budget Forecasts

Like the demands of every business, maintenance and reliability teams have the constant requirement to do accurate budget forecasts.

![]()

With limited visibility to external factors, changes in labor costs, unexpected equipment upgrades and uncertainty in failure predictions can result in deviations. Adopting rolling forecasts and allowing for budget flexibility ensures predictive maintenance adapts to real-time changes and maintains accurate financial planning.

Common Maintenance Questions Faced Across Industries

Whether it’s transportation, manufacturing, utilities, or aerospace, maintenance and reliability teams often face recurring questions that impact operations, budgets, and safety. Here are just a few examples of the real-world challenges professionals are trying to solve –

Transportation

Should I replace the wheelset on my locomotive or can I wait for a few months?

What maintenance activities should I perform on my freight car?

What are the bad actors in my fleet?

Manufacturing

What is the root cause of the equipment failure?

Should I scrap this machine or try to fix it?

What is the remaining useful life of my equipment?

Utilities

When is my solar panel or turbine expected to fail?

Which components in my system are likely to fail in the next month?

Will my asset survive the next trip?

Aerospace

What is the likelihood of delay due to mechanical issues?

When is this aircraft component likely to fail next?

Are there any parts to replace before the trip?

Our predictive analytics offering helps MRO professionals identify potential problems before they occur. This proactive approach allows for faster response times, better asset performance and lower overall costs associated with unexpected downtime or equipment failure.